Tracking process by Technomark Combo

Aiming to improve the traceability process of metal structures and parts produced by ROQ Laser, the company recently acquired the TECHNOmark Combo micro-percussion marking machine.

With the acquisition of this new equipment, ROQ Laser is meeting even more of its customers' needs, while also improving its quality process.

What is TECHNOmark Combo?

The TECHNOmark Combo micro-percussion machine is an ideal solution for manufacturing metal structures and parts that need to be engraved with traceable information, such as sequence numbers, names or even QR Codes.

The TECHNOmark Combo micro-percussion machine is an ideal solution for manufacturing metal structures and parts that need to be engraved with traceable information, such as sequence numbers, names or even QR Codes.

This machine can be used in workbench or portable mode, which is ideal for small or large parts.

It allows the marking of parts made from the most varied materials and solves identification, coding and traceability problems.

This type of engraving, unlike laser engraving, guarantees that even with the treatments carried out on the part, the engraving will not be damaged or fade.

Equipment 1-2 mode

With the new Combo solution, micro-percussion at ROQ Laser is even more versatile.

As it has a portable mode and a workbench mode, in less than 10 seconds it is possible to switch from one mode to the other without the need for major adjustments.

Workbench mode: The marking head is fixed on a column and can be easily adjusted. Ideal for small and medium-sized parts.

Portable mode: the user carries the wireless marking head up to a maximum distance of 10 meters from the marking station. Ideal for medium to large parts that are heavy or difficult to access.

Improvements in ROQ Laser's Quality process with this new traceability solution

Identification

Creates a kind of "identity" for the part, allowing relevant information about that structure or metal part to be known through this code.

Coding:

TECHNOmark Combo's coding process encompasses the possibility of engraving text, a numerical sequence, a date, a logo or even a QR code on the structure or part.

Traceability

This machine increases the value here. Both from the customers' point of view and for ROQ Laser.

From the customers' point of view:

With the code engraved on the part, ROQ Laser's customers can quickly see that we are the supplier. This way, we can provide them with important information that may be associated with the engraved codes.

In addition, with this engraving, ROQ Laser continues to ensure that it complies with the law requiring product traceability for the protection of the end consumer and the parties involved.

The equipment also helps with the quality and efficiency improvements that ROQ Laser has been implementing, following the path of Industry 4.0

From ROQ Laser's point of view:

We are able to know in detail the history of the machine, structure or metal part that we send to each customer, guaranteeing that they were produced at ROQ Laser.

It is also possible to know the raw material, the operator who made the part and, combined with the traceability that exists in our factory, it is possible to determine the consumables, certificates, production orders, among others.

This is important for predicting the lifespan of metal parts and understanding, if a preventive measure is taken, whether or not it has had any effect.

The usefulness of this machine is endless due to the fact that it can be used at numerous stages in the life cycle of the machines, metal structures and parts that ROQ Laser produces.

Use of the machine at ROQ Laser

1. Configuring the element to be engraved

2. alignment with the part

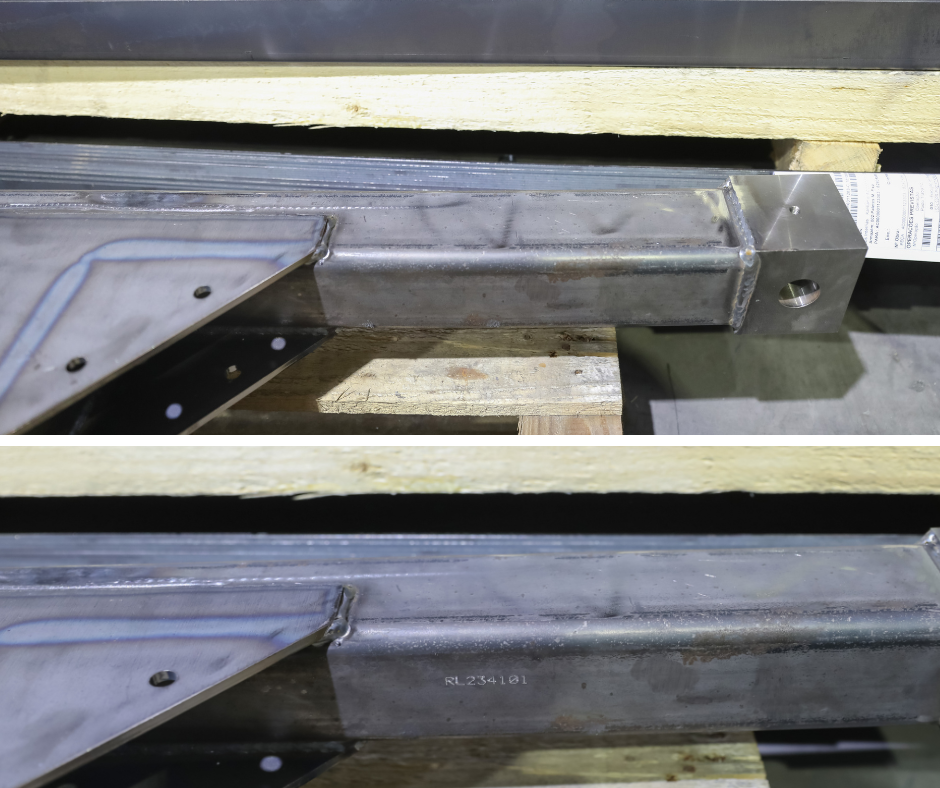

3. Engraving with micro-percussion

Process and product improvement

With the acquisition of the TECHNOmark Combo machine, ROQ Laser is taking another step towards further improving the manufacturing process and the end product.

With the implementation of this machine on the production line, 100% traceability is now possible.

It is possible to know details such as the certification of the material that has been used, all the operations carried out, the production dates, among many other relevant data for a quick response to any questions that may arise.

Therefore, on the machines, metal structures and parts produced by ROQ Laser, it is perfectly normal to see codes or other types of engraving created by our Quality and Industrialization teams.